Different drilling and tapping machines are well used in many manufacturing industries because of their many benefits. Here are just a few of those benefits:

Well-known advantages include:

- Fast and easy to install requiring no added skills to do the job.

- Highly versatile in nature rim and screws and a predetermined depth.

- Being a low maintenance option to provide long-lasting results.

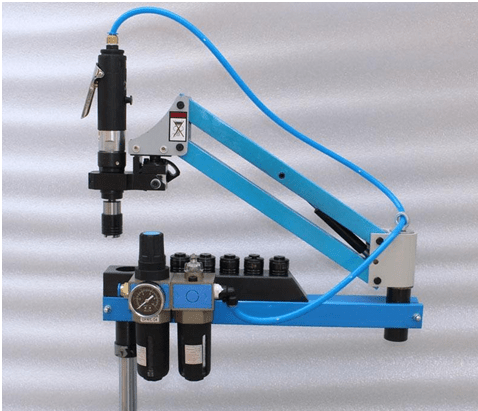

- Machines made of top-grade components such as spindles, gears, and shafts.

- The good arrangement provided with multiple spindle speeds.

- No attachments and accessories required for precision work.

- Footswitch facilities in an emergency.

By using a combination that includes both drilling and tapping machines, mass production can be easily achieved here because, with good knowledge and detail of the products, the machines do not cause any kind of damage during the operation. Basically, it is the design, technical skills, and professional expertise that set the industry standard that provides high-quality pioneering and high-performance tapping machines. For more information on Tapping Machines, visit a site like Cotswold Machinery Sales, a leading supplier of Tapping Machines.

Tapping machines are always faster and more accurate as they eliminate the frequent damage to the taps, as well as any inconsistency in the quality of the tapping. With machine tapping, the potential for human error is eliminated. The use of a tapping machine will accurately align the holes exactly as you want them.